Supply chain management is a crucial aspect of many businesses, and interviews for related positions often include questions to assess a candidate’s knowledge and experience in this field. Whether you’re a fresh graduate or an experienced professional, being well-prepared to answer questions about supply chain management can significantly increase your chances of landing the job. This guide will help you navigate through common interview questions and provide effective strategies to showcase your expertise.

Understanding Supply Chain Management

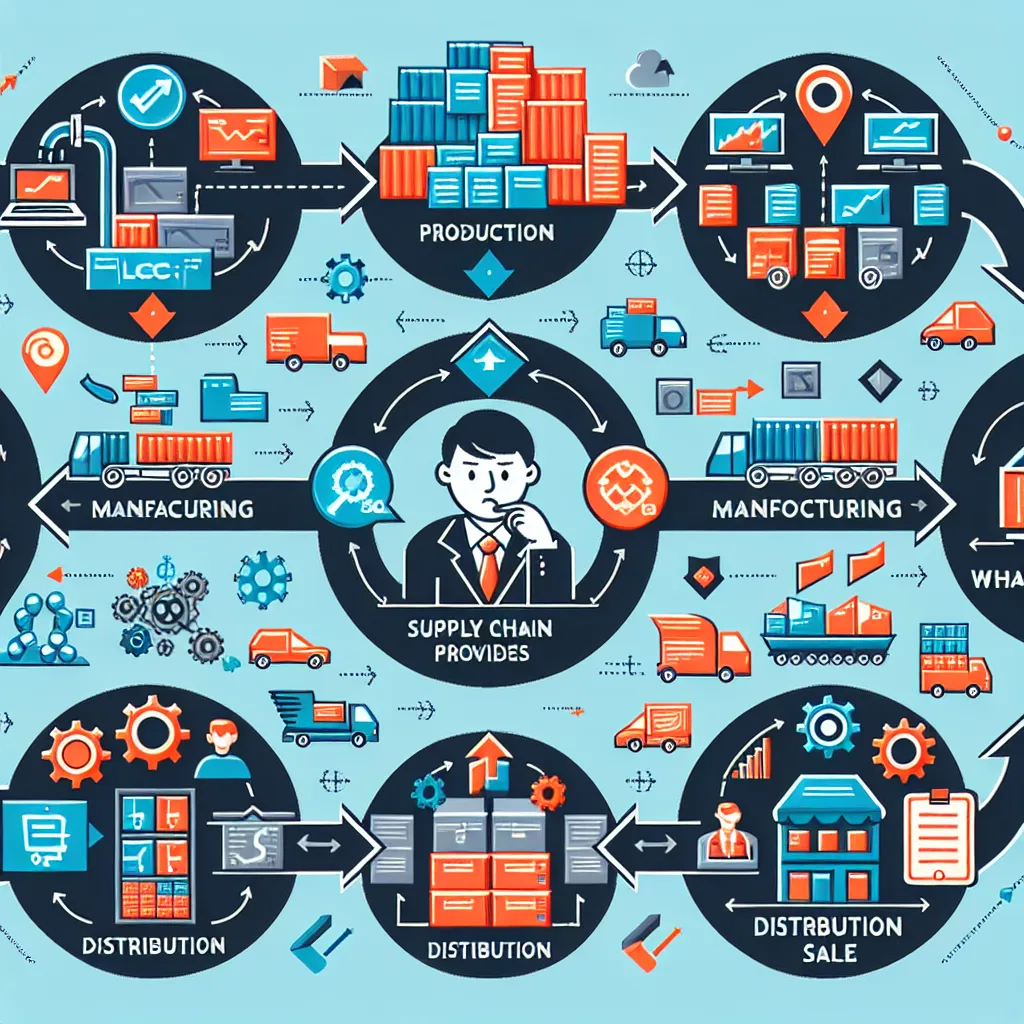

Supply chain management (SCM) involves the coordination and optimization of all activities involved in producing and delivering a product or service, from raw material sourcing to final delivery to the customer. It encompasses various aspects such as procurement, logistics, inventory management, and customer service. In today’s globalized business environment, effective supply chain management is essential for maintaining competitiveness and ensuring customer satisfaction.

Supply Chain Management Diagram

Supply Chain Management Diagram

Key Aspects Employers Evaluate in Supply Chain Management Interviews

When interviewing for a supply chain management position, employers typically assess candidates based on several key areas:

- Technical knowledge: Understanding of SCM principles, methodologies, and technologies

- Problem-solving skills: Ability to analyze complex supply chain issues and propose solutions

- Communication skills: Capacity to explain technical concepts clearly and collaborate with diverse stakeholders

- Strategic thinking: Ability to align supply chain operations with overall business objectives

- Adaptability: Flexibility in dealing with changing market conditions and supply chain disruptions

Common Supply Chain Management Interview Questions and Sample Answers

1. Can you explain the concept of ‘Just-In-Time’ inventory management?

Sample answer: “Just-In-Time (JIT) inventory management is a strategy aimed at increasing efficiency and decreasing waste by receiving goods only as they are needed in the production process. This approach minimizes inventory costs, reduces storage space requirements, and improves cash flow. For example, in the automotive industry, manufacturers often use JIT to receive components from suppliers precisely when they’re needed on the assembly line, reducing the need for large warehouses and the risk of obsolete inventory.”

2. How would you optimize a company’s supply chain to reduce costs?

Sample answer: “To optimize a supply chain and reduce costs, I would start by conducting a thorough analysis of the current supply chain structure. This would involve:

- Identifying inefficiencies and bottlenecks

- Evaluating supplier relationships and negotiating better terms

- Implementing demand forecasting tools to improve inventory management

- Considering transportation consolidation to reduce shipping costs

- Exploring automation opportunities in warehousing and distribution

For instance, in my previous role, we implemented a new inventory management system that reduced our carrying costs by 15% and improved our order fulfillment rate by 10%.”

3. How do you handle supply chain disruptions?

Sample answer: “Handling supply chain disruptions effectively requires a proactive approach and quick response. My strategy includes:

- Developing contingency plans for potential disruptions

- Maintaining strong relationships with multiple suppliers

- Implementing real-time monitoring systems to detect issues early

- Creating a cross-functional team for rapid response

- Regularly reviewing and updating risk management strategies

For example, during the COVID-19 pandemic, we quickly activated our business continuity plan, which included shifting to alternative suppliers and adjusting our inventory levels to ensure we could meet customer demands despite global supply chain challenges.”

4. What metrics do you consider most important in supply chain management?

Sample answer: “The most critical metrics in supply chain management often depend on the specific goals of the organization. However, some key metrics I consistently monitor include:

- On-time delivery rate

- Inventory turnover ratio

- Perfect order rate (orders delivered on time, in full, and error-free)

- Cash-to-cash cycle time

- Total supply chain costs as a percentage of sales

These metrics provide a comprehensive view of supply chain performance, efficiency, and customer satisfaction. For instance, improving the perfect order rate directly impacts customer satisfaction and can lead to increased repeat business.”

Tips for Answering Questions Outside Your Expertise

- Be honest about your knowledge gaps

- Express enthusiasm to learn

- Relate the question to your existing knowledge

- Ask clarifying questions

- Provide an example of how you’ve quickly learned new concepts in the past

Common Mistakes to Avoid in Supply Chain Management Interviews

- Failing to provide specific examples from your experience

- Not staying updated on current supply chain trends and technologies

- Overlooking the importance of soft skills in supply chain management

- Focusing solely on cost reduction without considering other factors like quality and sustainability

- Underestimating the complexity of global supply chains

Supply Chain Management Interview Preparation

Supply Chain Management Interview Preparation

Follow-up Interview Questions and Answer Suggestions

-

How do you stay updated on the latest trends in supply chain management?

Suggestion: Mention industry publications, conferences, and professional networks you follow. -

Can you describe a time when you improved a supply chain process?

Suggestion: Use the STAR method (Situation, Task, Action, Result) to structure your response. -

How do you balance cost efficiency with sustainability in supply chain operations?

Suggestion: Discuss the importance of long-term thinking and provide examples of sustainable practices. -

What role does technology play in modern supply chain management?

Suggestion: Highlight key technologies like AI, IoT, and blockchain, and their potential impacts. -

How do you approach supplier relationship management?

Suggestion: Emphasize the importance of collaboration, clear communication, and mutual benefits. -

Can you explain the concept of supply chain visibility and its importance?

Suggestion: Discuss how visibility impacts decision-making and risk management. -

How do you handle conflicting priorities in supply chain management?

Suggestion: Describe your approach to prioritization and stakeholder management. -

What strategies would you use to reduce lead times in a supply chain?

Suggestion: Mention concepts like process optimization, supplier collaboration, and lean principles.

Conclusion

Mastering the art of answering questions about supply chain management in interviews requires a combination of in-depth knowledge, practical experience, and effective communication skills. By understanding the key aspects that employers evaluate, preparing for common questions, and avoiding typical mistakes, you can significantly improve your chances of success. Remember to provide specific examples from your experience and demonstrate your ability to apply supply chain concepts to real-world situations. Stay updated on industry trends and be prepared to discuss how you can add value to the organization’s supply chain operations.

For more interview preparation tips, check out our articles on how to answer questions about your future plans and how to prepare for an operations interview.